Sintered Brake Pads and Clutch Materials for The Industrial Industry

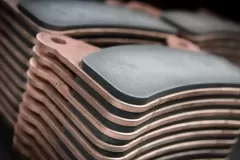

Our high-energy brake materials, low-wear friction materials, and sintered brake pads are popular in the industrial market, which also boasts plenty of GMP success stories.

One of our customers, a manufacturer of a battery-powered nailer came to us looking for a clutch material that could meet some challenging stipulations. Not only does the nailer spin at 10,000 rpm, generating a very high instantaneous-energy demand, but the clutch has a one-of-a-kind mechanical configuration, thus the friction material also had to have just the right amount of slip, and wear was a serious concern. GMP met all these requirements with a high-energy, low-wear friction material for the clutch.

GMP not only solves such challenges, but is also committed to both quality and excellent customer service. Recently, a forklift manufacturer that could never seem to get satisfactory customer service from their vendor turned to GMP Friction Products. We supplied them with a friction material that outperforms what they had been using, and we continue to meet their increasing demand. We have a great relationship with this customer, who appreciates our courteous customer service, especially since they said their previous vendor treated them as “a little fish in a big pond.”

Additional GMP components in this market include spring-applied, hydraulic-release brakes, electromagnetic clutches, overload clutches, torque-limiting clutches, and dry brakes, which appear on man lifts, cranes, hoists, winches, material-handling and other industrial equipment.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141